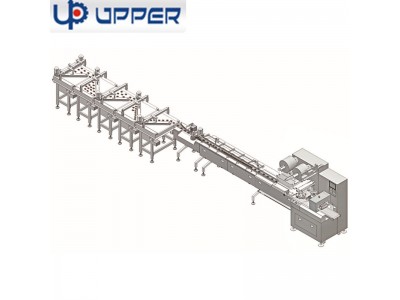

| Mode | UPB-UPX-QKL |

| Packing size | 600/800mm/1000mm |

| Capacity | 50-600packs/min |

| packing Material | OPP/PE,OPP/CPP and complex film |

| Power Supply | 220V 50 HZ |

| Total Power | 3.2KW |

| Net Weight | According to atual situation |

| Outer Dimension(L*W*H) | According to atual situation |

Our packing machine is combined of many years research and development, production and perfect the essence of innovation. The machine has the advantages of clear sealing, good sealing, tidy, beautiful appearance, compact structure, easy and flexible operation, fast running, smooth, low noise and so on. Mainly used in the egg yolk pie foods, biscuits etc. There is a set of charging device, can give the packaging inflatable, effective protection of the packaging objects. After our trial for a long time, the main electrical control components of the machine performance is stable, safe and reliable. The characteristics of machines are as follows:

|

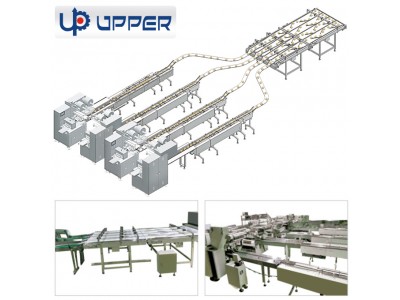

1. The front conveyor belt of this line can be connected with the outfeed conveyor belt of user's front-end production line for fullautomatic continuous feeding and packing, or by manual 3 products dumping on the conveyor belt for conveying and packing. 2. The packing line can be customized according to user's individual requirements. 3. With multi-stage frequency conversion for speed adjustment, servo control and intelligent PLC control system, it is characteristic of simple operation, stable running, high control accuracy and low energy consumption. 4. Color LCD touch screen with intuitive HMI display for parameters setting. Fault self-diagnostic display on the screen helps trouble shooting. 5. The data memorystorage function helps to change product sizes. 6. Automatic defective product rejecting function is available to ensure continuity and stability of production. 7. High precision and high sensitivity SICK brand photo sensor tracking system ensures accurate product positioning. 8. The machine configuration is made of complete stainless steel and alu-alloy profiles. With user- friendly design, it is simple and fast in installation, disassembly, repair and maintenance. 9. At user's demand, extra units of code printer, inkjet printer, air charging device or alcohol spray device can be equipped on the machine for different purpose. |

You may like

-

$24000.00/packing ma

-

$24000.00/packing ma

Chocolate Pillow Packing Machine with Automatic Feeding Line

-

$22000.00/packing ma

-

$12000.00/packing ma

-

$2800.00/automatic

-

$4600.00/packing ma

-

$4600.00/packing ma

-

$4800.00/packing ma

-

$4500.00/packing ma