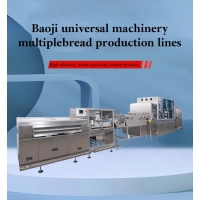

This machine adopts precise control that integrates light, electricity, and steam, with a high degree of automation. The double twisted dragon is used as the power output for supplying leather and filling materials, supplemented by pressure rollers to ensure uniform feeding. The blade pump is used for metering, and the forming tool moves up and down while receiving the knife. The conveyor belt then starts and stops, ensuring that the product will not deform due to the movement of the conveyor belt. The unique cutter gap adjustment function ensures uniform closing and extends the service life of the cutter. The embryo of a mooncake can be stamped up and down on the mooncake mold to form any desired geometric (circular, square, elliptical) shape mooncake. The operating system adopts PLC and touch screen. The product weight, leather filling ratio, and production speed can be adjusted infinitely within the specified range. Make device operation easy to learn and understand.